The photovoltaic station in question is located at “Gouva Batsi”, Municipal Community of Salamina.The area of the plot is 6,740.71 sq.m and the total area covered by the PV panels is 5,234,798 sq.m.

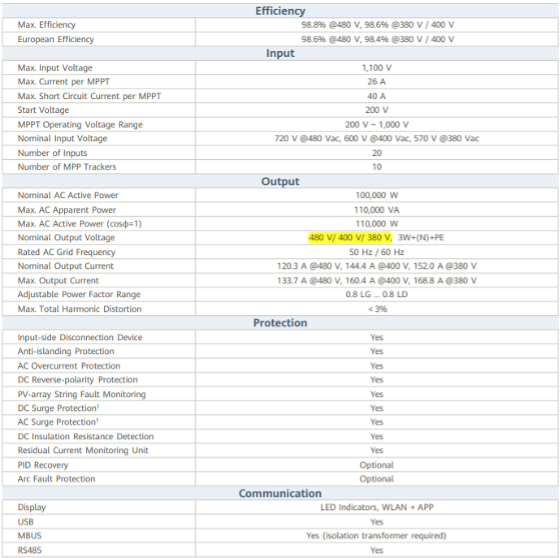

POWER INVERTERS

The inverters are from the Chinese manufacturer Huawei and are three-phase, "string inverter" type and have protection (watertightness class) IP65 for external installation (outdoor installation). A total of 5 inverters were installed. The type of inverters is Huawei 100 KTL - M 0

CE certification and follow the following safety standards:

• IEC/EN 62109-1, IEC/EN 62109-2, EN 61000-6-2, EN 61000-6-3, EN 61000-3-11, EN 61000-3-12

They also follow the following network standards:

• CEI 0-21, CEI 0-16, DIN V VDE V 0126-1-1, VDE-AR-N 4105, G59/3, EN 50438 (not for all national appendices), RD 1699, RD 413, RD 661, PO 12.3, AS 4777, BDEW, NRS-097-2-1, MEA, PEA, IEC 61727, IEC 60068, IEC 61683, VFR-2014, IEC 62116

KVA power substation was installed at the south-west point of the plot to concentrate the power from the inverters with the least losses. It includes an area of Fields M.T. 20kV, 500KVA M/S area and Low Voltage General Panel area. Under the floor of the cottage both the M.T. cables run. as well as the X.T and communication cables.

MT fields

SM6-24 metal clad scopes of its ADVAN6 series have been installed company SCHNEIDER ELECTRIC (SE) suitable for indoor installation (Switchboard Serial Number: S22A14001).

M/S power 500KVA, 20/0.4KV

A 500KVA, 20/0.4KV M/S of ABB has been installed in it Okisko Control (Serial Number: 1LTR0050960, Type Number: 21880).

General Table H.T.

General H.T. Board has been installed. nominal intensity 800 A inside the House Control ( Serial Number : T 21 K 38001).

The routing of the high current cables was carried out in a separate pipe from the weak current cables.

DC CABLES

For the electrical connection of the PV panels to each other, a special type of cable was used, where the conductive material of the cable is copper, of suitable cross-section, flexible, non-flammable and has specifications for protection against ultraviolet radiation and operation at high temperatures.

CABLES A .C

AL / XLPE / PVC type cables were used for the AC part of the PV Station.

COMMUNICATION CABLES

• UTP cable for image transmission from cameras

• LIYCY(TP) for transmitting signals from the inverters and other sensors to the control center

Protection of the General Installation Panel H.T. from direct and indirect AC lightning strikes.

The PV Station in question is connected to the local MV Network. (20kV-DEDDIE) and specifically in the existing P-270 distribution line of the SALAMINAS S/S.